Our mission is to give freedom back to active men, while protecting the planet. So to combine elegance and technicality while respecting our values, we make strict choices. To produce in Europe, with responsible partners and materials.

Today we're telling you why we chose Tencel® rather than cotton for our first white shirt.

1) What is Lyocell / Tencel®?

It is an artificial fibre -created by man- based on a natural component: cellulose from boi pulps.

The technical process (known as ‘solvent spinning’) was invented in 1972 in the United States by the company Enka, then marketed under the name Tencel® by the British company Courtaulds.

Bought by Lenzing, the Austrian textile giant, in 2004, Tencel® is therefore a BRAND of Lyocell. The best known in the world today. The one we use.

2) How is Tencel ® made?

The wood is debarked and cut into several small pieces. Amine oxide, a non-toxic solvent recovered at 99.7% and reused during production, will then dissolve the cellulose in heated and pressurised vessels. The solution is filtered and pumped through spinnerets, to give long strands of Lyocell fibres. These are then cleaned, carded, combed and possibly dyed before being spun.

Le bois est écorcé et coupé en plusieurs petits morceaux. L’oxyde d’amine, un solvant non toxique récupéré à 99,7% et réutilisé au cours de la production, va ensuite dissoudre la cellulose dans des récipients chauffés et pressurisés. La solution est filtrée et pompée à travers des filières, pour donner des longs brins de fibres de Lyocell. Ceux-ci sont ensuite nettoyés, cardés, peignés et éventuellement teints avant d’être filés.

The production cycle is short. It takes 2 ½ hours from wood cutting to spinning. It uses less water and energy than other processes, and generates no harmful by-products.

3) What are the technical properties of Tencel ®?

While we're on the subject of clothes, that's what we're primarily interested in!

- The major advantage for our Wolbe range is that Tencel® has a NATURAL REPIRABILITY. Made up of a multitude of small hydrophilic fibres, it absorbs moisture even better than cotton and dries much faster. It therefore reduces the appearance of rings under the arms and the very unpleasant sensation of fabric sticking to the skin after a little acceleration...

- Its antibacterial properties are well known. Without transpiration, there is no real breeding ground for bacteria.

- It offers a pleasant sensation of freshness on the skin in summer.

- It is very soft, light and comfortable. Its surface is smooth and silky. It is perfect for sensitive skin. However, its performance will be too fluid to consider 100% Tencel® fabric in formal menswear. It will have to be blended (with wool or recycled polyester).

- Finally, Tencel® is durable. Its elasticity and crease resistance make it a fabric that is easy to care for.

4) Is Tencel® eco-responsible?

Definitely Yes.

- It is obviously biodegradable.

- It requires 10 times less water than cotton during its manufacture (1000 litres/kilo). The forests are generally neither irrigated nor treated.

- It produces 10 times more material than cotton, per hectare cultivated

- And 100% of the wood is used, without waste: 40% will be used for pulp, 10% to extract bio-based materials (acetic acid, xylose...) and 50% will be recycled as energy.

5) Why is Tencel® better than cotton?

To understand our reasoning, we first need to set some context. To produce the 100 billion garments sold around the world every year (x2 in 10 years!), the textile industry manufactured 111 million tonnes of fibre in 2018.

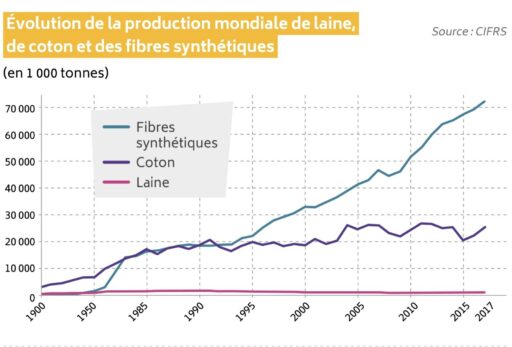

Synthetic fibres (polyester, nylon) unfortunately largely dominate this production: 69% of the total, with 72 million tonnes. And at a staggering rate of growth (see graph below).

Cotton is the most widely produced natural fibre in the world.

With 27 million tonnes, it accounts for 84% of the volume of natural fibres produced, ahead of wool and linen. China and India account for 50% of global production, just ahead of the United States.

But cotton is very demanding when it comes to climate requirements!

Its cultivation requires 120 days of heavy rain during the growing season, and an even longer period of sun, heat and drought to ripen the seeds! This ‘contradictory’ requirement makes it a less than eco-responsible crop.

And even if there are several different varieties of cotton (supima, sea island, Egyptian, etc.) or developments on the organic side, the figures for its cultivation worldwide are impressive:

- 2.5% of cultivated areas...but 25% of insecticides and 10% of herbicides used worldwide -source WHO-.

- 64% of the volume cultivated is genetically modified.

- And, an absolutely key point for us: it takes 10,000 litres of water on average to produce a kilo of cotton fabric (6,000 in China, 22,500 in India) -source Water Footprint network-.Maize requires 1,220 litres/kilo by comparison and wheat 1,000.